Class 67 Thomas Telford

A New 7¼” Ground Level Locomotive for Ashton Court

Latest update – Thomas Telford goes Public

Thomas Telford commenced public service over the August Bank Holiday weekend.

It operated throughout the weekend without a hitch and a number of members took the opportunity to drive. All were complimentary regarding the simplicity of control and the ease which it handled the load.

A test run was carried out with 7 carriages and 42 passengers plus the driver. The train pulled away with a hint of slipping and completed two laps in style much to the excitement and relief of all.

The photos below show ‘The Body’, ‘On the Track’, ‘The First Run’ and ‘Some of the Team’.

|

|

Details

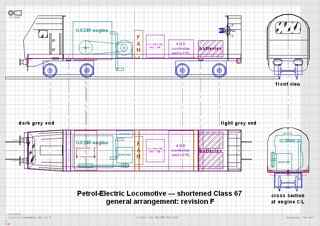

The locomotive will be petrol electric based on the Class 67 Diesel 67014 – Thomas Telford. A single ended version of this locomotive was designed for Virgin operation but never produced and this will form the basis of our new engine. Whilst representing a modern locomotive this version provides a flat end for the controls and instrumentation and keeps the length down to a manageable 8ft.

In the 7¼” version a Honda GX240 petrol engine will power a 24v commercial vehicle alternator, complete with its rectifiers and voltage regulator. This will charge two 12v vehicle batteries. A standard 4QD controller will control the power from the batteries to two Parkside 1500watt four wheeled bogies. The frame will be steel angle of welded construction with a body formed by a specialist sheet metal supplier – Manuflex (http://www.manuflex.co.uk) Ample power of some 3hp should be available to haul heavy loads throughout a running day and the limiting factor is likely to be the adhesion of the wheels on the rails.

Mark Phillips is doing the design with Bob Lilley managing the project together with the controls, instrumentation and electrical wiring. Frames have been built by Tim Hims, with mechanical assembly of the main drive by Colin MacEke. Phil Bridgeway is looking after the vacuum system and Don Cordall the handbrake. Geoff Hinbest is pulling the paper work together and will produce a handbook and maintenance schedule. Ron James is producing the forced ventilation system and Mike Keighley, Andy Field, Terry Phelps and Colin Ball will be working on the body detail. Andy Nicholls has volunteered to make the buffers and Andy Harding the throttle and choke controls.

The photographs give a good indication of the component parts of the locomotive.

|

|

|

|